RD314 Brake Pads One Time Formation Cold Pressing Machine

RD314 200/300T Cold-Press Temporary Molding machine is able to have mixed material molded by cold press through back steel and desulfurized in oven by high temperature. It has the characteristics of simple operation, low cost equipment but of high efficiency and products improved. It is the preferred products both for field-testing and in machine since they are stable in inner nature which results from manufacture without material flowing in heat-press. We have various kinds of prescriptions available made specifically with cold-press technique and 200T/300T of the two types.

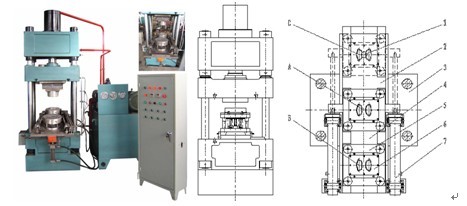

The cold-press mold machine is composed of weighing system, press, hydraulic powered sliding plate and molds for cold-press molding. Two operators are needed because three operating places are stationed. PLC controls the entire process when it starts. When hydraulic sliding plate goes right to the place as illustrated, press moves down to mould the material in the mould in A. Meanwhile operator in B lifts up and fills the mixed material into the mould one by one. The back steel should be located in the moulds after the above has been done. The press retracts after finishing molding, then hydraulic sliding plate tracts forwards the molds in B to A. At the same time molded material in A has moved to C by sliding plate. Operator in A presses again and repeats the same procedure as shown.

When it works, air comes in from the down hole of the cylinder controlled by pneumatic door. The sliding plate moves to the stipulated location after the pneumatic door opens, where pre-formed materials in compound moulds are taken to the edge of the plate and lifted up right to the position where heat moulds are stationed. The pre-formed materials are pressed into the heat-molding moulds and the working plate moves into the ram after fixed by the back steel. When pneumatic door closes, the press moves down to heat and exert pressure for some time until it satisfies the time required. When pneumatic door opens again, working plate goes to mould-off place where signal transmits from proximity switch for pushing ram to move the heat-pressed mould out while the pressed brakes are pushed out of mold.

1.Cylinder for stripping 2.Fixed plate 3.Hydraulic press 4.Sliding plate

5.Mould supporting 6.Mould 7.Cylinder for driving

[Home]

product >RD314 Brake Pads One Time Formation Cold Pressing Machine