[Home]

product >RD300 Perform Press for Disc Brake Pads

RD300 Perform Press for Disc Brake Pads

There are types of 1000KN / 2000KN and 5000KN pre-molding press classified as different pressures they produce. 2000KN and 5000KN are for pre-molding of drum brake, 1000KN for disc brake pads only.

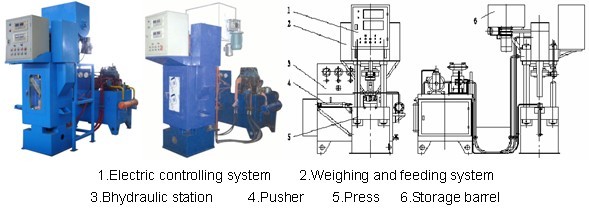

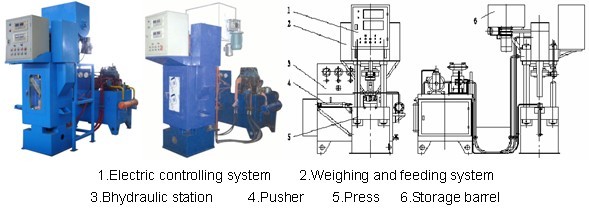

RD300 is built up with presser, hydraulic parts, storage barrel, weighing & transmitting system, brake-ejected device, electric controlling system and mantle (unshown)

This machine greatly improves production efficiency and products quality. It brings none pollution in the process of brake pre-molding by the complete auto operations of weighing, feeding controlled by PLC.

Before starting, mixed material should be put into the barrel first. Certain amount of material is weighed by weighing system before filled into the pre-mould. The cylinder moves male mould down to press till certain pressure reaches the requirement and then quickly lifts up. The ejector retreats with male mould coming down to strip the ready-made brake to the bottom plate. The pusher pushes brakes to the production line for the next stage.

There are types of 1000KN / 2000KN and 5000KN pre-molding press classified as different pressures they produce. 2000KN and 5000KN are for pre-molding of drum brake, 1000KN for disc brake pads only.

RD300 is built up with presser, hydraulic parts, storage barrel, weighing & transmitting system, brake-ejected device, electric controlling system and mantle (unshown)

This machine greatly improves production efficiency and products quality. It brings none pollution in the process of brake pre-molding by the complete auto operations of weighing, feeding controlled by PLC.

Before starting, mixed material should be put into the barrel first. Certain amount of material is weighed by weighing system before filled into the pre-mould. The cylinder moves male mould down to press till certain pressure reaches the requirement and then quickly lifts up. The ejector retreats with male mould coming down to strip the ready-made brake to the bottom plate. The pusher pushes brakes to the production line for the next stage.