[Home]

product >RD311 Six Layers Heat Press for Disc Brake Pad

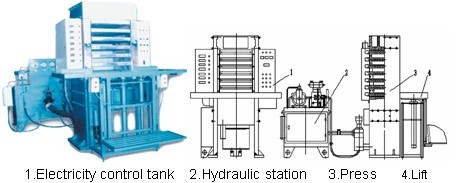

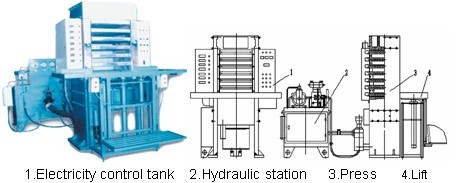

RD311 Multiple Layers Heat Press’╝ł200T/250T/300T/400T’╝ē

There are 300T and 400t of this kind of machine for the different loads required. It is composed of press, hydraulic station, electric controlling system and the lift. Liftman will only put the pre-molding material into the moulds manually because all of other performances are done automatically controlled by PLC. The electric controlling system controls the press, deflation, time to eject brakes by the data preset by technician on MPT that cannot be modified. This ensures the consistency and stability of the products. What’s more is that our hydraulic system powered by 7.5KW engine reduces consumption of power in a large amount.

The 6 layers moulds work at the same time for pressing, but moulds are only removed one after another done by the liftman on the lift up or down. Pre-mould material is also necessary to be put into the moulds manually.

There are 300T and 400t of this kind of machine for the different loads required. It is composed of press, hydraulic station, electric controlling system and the lift. Liftman will only put the pre-molding material into the moulds manually because all of other performances are done automatically controlled by PLC. The electric controlling system controls the press, deflation, time to eject brakes by the data preset by technician on MPT that cannot be modified. This ensures the consistency and stability of the products. What’s more is that our hydraulic system powered by 7.5KW engine reduces consumption of power in a large amount.

The 6 layers moulds work at the same time for pressing, but moulds are only removed one after another done by the liftman on the lift up or down. Pre-mould material is also necessary to be put into the moulds manually.