[Home]

product >RD362 Brake Pads Scorching Machine(for American Honeywell Lengthened Type)

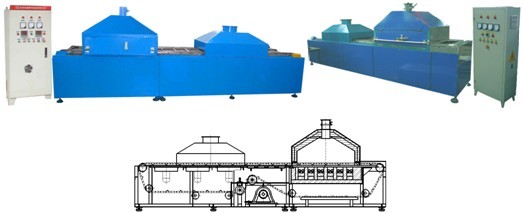

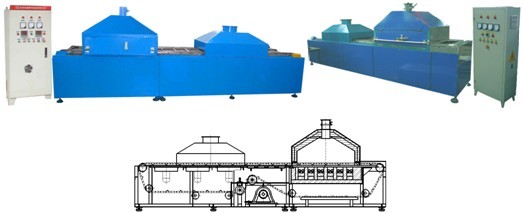

RD362 Brake Pads Scorching Machine (for American Honeywell Lengthened type)

RD362 type scorching machine is specially designed for disc brake pads surface temperature scorch processing. Organic substances of brake pads friction surface under temperature effect will be decomposed and evaporated,can prevent forming air cushion in initial brake process,causing lowering of brake efficiency,obviously improving hot declining feature of brake lining,under temperature effect, friction performance of friction material is improved,brake process is stable,and can reduce the possibility of occurring brake noise. Permeation of temperature in scorching process, can also enable brake pads to occur necessary expansion, thus reducing the harmful hot expansion.

Brake pads is placed into scorching machine inlet,pushed by pushing plate of pads sending mechanism,in due order, through high temperature scorching section, cooling section,equipment temperature in complete scorching machine process is automatically controlled, pushing speed can be adjusted,aiming at different brake lining product,can convenient adjust scorching temperature and the maintaining time of brake pad under scorching temperature, satisfy different process requirements,it is a special equipment with high performance and efficiency integrated with mechanic and electric.

RD362 type scorching machine is specially designed for disc brake pads surface temperature scorch processing. Organic substances of brake pads friction surface under temperature effect will be decomposed and evaporated,can prevent forming air cushion in initial brake process,causing lowering of brake efficiency,obviously improving hot declining feature of brake lining,under temperature effect, friction performance of friction material is improved,brake process is stable,and can reduce the possibility of occurring brake noise. Permeation of temperature in scorching process, can also enable brake pads to occur necessary expansion, thus reducing the harmful hot expansion.

Brake pads is placed into scorching machine inlet,pushed by pushing plate of pads sending mechanism,in due order, through high temperature scorching section, cooling section,equipment temperature in complete scorching machine process is automatically controlled, pushing speed can be adjusted,aiming at different brake lining product,can convenient adjust scorching temperature and the maintaining time of brake pad under scorching temperature, satisfy different process requirements,it is a special equipment with high performance and efficiency integrated with mechanic and electric.