[Home]

product >RD4510 Light Vehicle, Heavy Duty Vehicle Brake Lining NC (Single Row, Double Row) 10 Hole Drilling M

RD4510 Light Vehicle, Heavy Duty Vehicle Brake Lining NC (Single Row, Double Row) 10 Hole Drilling Machine

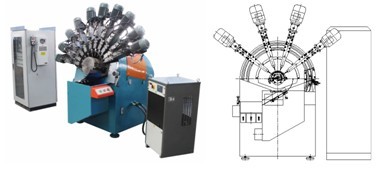

Xianglong Friction Material Machinery Co., Ltd, according to characters of large demand for brake shoe riveting brake lining in North America, South America, Europe and Middle East,has developed RD4510 type car, light vehicle, heavy duty vehicle brake lining multiple functional NC 10-hole drilling machine. It is applicable for drilling and grinding holes for sedan car, mini-type car, light vehicle, heavy duty vehicle brake linings, particularly applicable for the drilling of thin drum brake linings. Equipment is shown as Fig.

It is equipped with 10 sets of independently working hydraulic power heads, the position can use manual small gear box, very easily conduct adjustment. It has independent electric control system, adopts button centralized control, can realize adjustment(manual), automatic etc. Working mode, electric control can select German Siemens, Japanese Mitsubish as well as China Huazhong NC Century Star special computer control system to conduct procedure control on high precision servo motor, which has entirely realized automatic production. Equipment operation is simple, convenient for maintenance, greatly raised drilling precision and productivity, lowered production cost.

The machine electric cabinet possesses dust-proof and water resistant functions, the protection class is IP65.Inside of the cabinet adopts advanced touch type air conditioned cooling machine for cooling, in order to ensure the reliability of machine working.

The machine hydraulic system adopts plate type slide valve system, possessing characters of less leakage, high efficiency and convenient maintenance, hydraulic oil cooling adopts independent air conditioned touch type cooling machine, controlled by computer automatically.

The machine is equipped with a lot of dust sucking meeting openings, which has greatly lowered the influence on working environment and operator’s heath when machine is working by dust pollution.

The machine main axis feed stroke and speed, hydraulic power head position, feed volume, feed pressure, feed speed, drilling stemextension etc. can be adjusted according to process need within the stipulated scope.

Its drilling and grinding precision is high, processing product quality is stable, one time can feed a lot of piece, with high production efficiency(one shift can produce 3000~6000pcs).

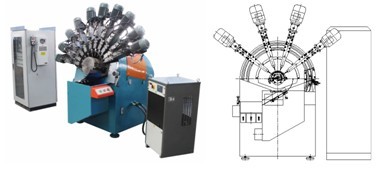

Xianglong Friction Material Machinery Co., Ltd, according to characters of large demand for brake shoe riveting brake lining in North America, South America, Europe and Middle East,has developed RD4510 type car, light vehicle, heavy duty vehicle brake lining multiple functional NC 10-hole drilling machine. It is applicable for drilling and grinding holes for sedan car, mini-type car, light vehicle, heavy duty vehicle brake linings, particularly applicable for the drilling of thin drum brake linings. Equipment is shown as Fig.

It is equipped with 10 sets of independently working hydraulic power heads, the position can use manual small gear box, very easily conduct adjustment. It has independent electric control system, adopts button centralized control, can realize adjustment(manual), automatic etc. Working mode, electric control can select German Siemens, Japanese Mitsubish as well as China Huazhong NC Century Star special computer control system to conduct procedure control on high precision servo motor, which has entirely realized automatic production. Equipment operation is simple, convenient for maintenance, greatly raised drilling precision and productivity, lowered production cost.

The machine electric cabinet possesses dust-proof and water resistant functions, the protection class is IP65.Inside of the cabinet adopts advanced touch type air conditioned cooling machine for cooling, in order to ensure the reliability of machine working.

The machine hydraulic system adopts plate type slide valve system, possessing characters of less leakage, high efficiency and convenient maintenance, hydraulic oil cooling adopts independent air conditioned touch type cooling machine, controlled by computer automatically.

The machine is equipped with a lot of dust sucking meeting openings, which has greatly lowered the influence on working environment and operator’s heath when machine is working by dust pollution.

The machine main axis feed stroke and speed, hydraulic power head position, feed volume, feed pressure, feed speed, drilling stemextension etc. can be adjusted according to process need within the stipulated scope.

Its drilling and grinding precision is high, processing product quality is stable, one time can feed a lot of piece, with high production efficiency(one shift can produce 3000~6000pcs).