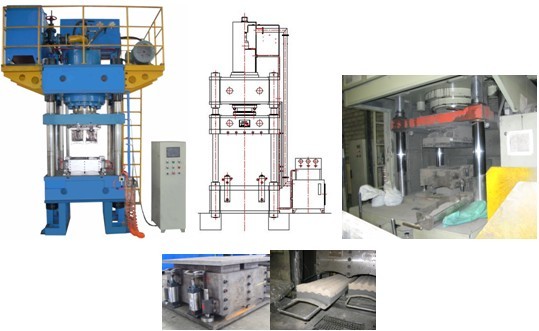

RD300 type 250T Preforming Press for Brake Linings

The machine is 4-column type structure hydraulic press, which is specially used for the friction material cold press process (preform press) for drum brake lining

The machine mainly consists of main machine, electric system; hydraulic press etc.Main machine consists of upper beam, oil cylinder, slide block, lower beam, column and column lock nut and so on.

The electric control system of the machine includes electric cabinet, air switch, PLC can program controller, man-machine, interface (touch screen), every control button, delay relay as well as other control electric appliance etc.Through man-machine interface as well as PLC can directly set related process as well as parameters.

The machine electric system applying button centrally control ,which can realize manual ,semi-automatic and automatic three kinds of working mdes.The machine work pressure as well as working stroke can be adjusted according to process e are as the following picture. Firstly, the operator pull the mold drag plank into the bottom of the mold,the cylinder that used for mold’s taking off start.There is a closed cavity formed by the downward mold cavity and the mold drag plank as well as the bottom of the mold.Then the operator filled the mold cavity with the fundus material packed by tailor-made plastic bag.The next step is to start the press,the main cyliner will go down and press the fundus material.when the material was pressed well,the cylinder will go upward.The worker put the feeding box with friciton material into the mold cavity,and then turn the handle of the feeding box.The bottom of the box will open so that the material fill into the mold cavity.After that,bring out the feeding box,the main cylinder will go downward.And the press will realize the press process according to the programed parameter.After finishing the preform press,the cylinder will leave about 1-2 CM,and the mold’s taking off cylinder act.As a result,the finished products take apart with the mold cavity.Tha main cylinder go upword,while the mold’s taking off cylinder cause the mold cavity sparate with its base part.

At last,pull the mold drag plank out and take out the product.when pull in the mold drag plank ,there will be the the next circle.

[Home]

product >RD300 type 250T Preforming Press for Brake Linings